Formulations currently exist for silver or aluminum based filler metals and it is available on spools or coils for wire feed applications or as preformed rings or shapes for automated brazing lines.

How to separate braze sheet metal.

Handy one is a flux cored product.

Do not quench materials with large differences in coefficients of thermal expansion to avoid cracks in the base materials and tears within the braze alloy.

Galvanized steel is a protected variety of the metal using the process of galvanization to prevent and repel corrosion.

I have heated up solder joints to separate pieces of sheet metal but what about braze and cast iron.

Soldering is a process that joins materials with a filler metal that has a liquidus not greater than 842ºf 450ºc.

Braze welding unlike brazing goes beyond capillary action and deposits a strengthening thickness or bead of brazing material in braze weld.

Finally brazing fluxes have a tendency to cause hydrogen embrittlement in the metal adjacent to brazed joints and this can cause cracking in that metal as panels vibration cycle over miles and time.

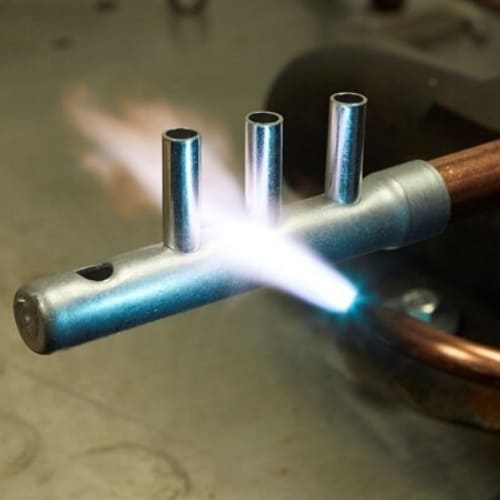

Braze welding bridges a gap using filler metal that is melted and deposited in fillets and grooves exactly at the points it is to be used.

I also have some really super thin body pieces that my mig welder just blasts holes through.

To be more precise it s a brazing alloy in strip form rolled around a powdered flux.

Tri foil is designed to artificially thicken a joint relieving stress and reducing the incidence of cracking.

Argo braze 502 tri foil is a composite material with the brazing filler metal on either side of a central copper core argo braze 502 tri foil is ideal for brazing large carbide pieces of more than 20mm in any dimension.

Because the galvanized metal is designed to be resistant to outside harm soldering pieces of steel that have been galvanized can pose a problem if done improperly.

Even if i turn my mig waaaay down the welds turn out like garbage or blow holes.

034 braze filler in the form of coiled melt spun foil is adhesively bonded to coiled parent sheet metal forming a coiled laminate which can be cut to desired shapes and brazed as an assembly comprised of laminate and non laminate parts.

Note that quenching can affect base material mechanical properties.

The absence of manganese in this filler metal gives it a.

Quench only after the braze filler metal has solidified to avoid cracks or rough braze joints.

I got a cast iron vice and the swivel base has been brazed to the vice body.

My car 1927 essex seems to dislike mig and i suspect due to the iron content in the sheet metal.

Because the parent metal and melt spun foil are cut at the same time only one piece of material must be handled.