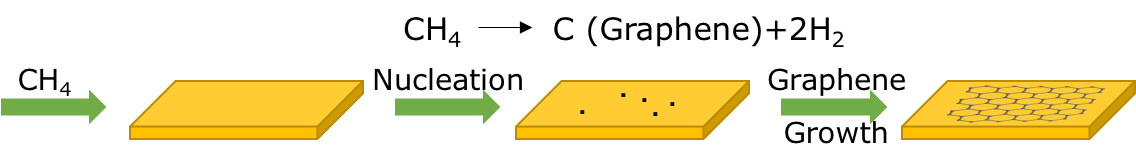

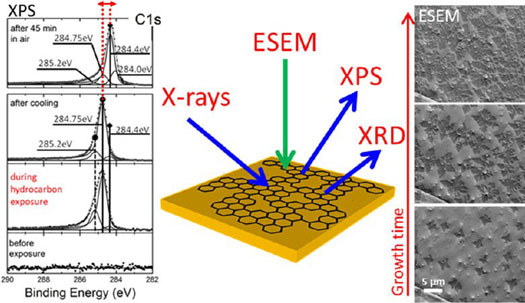

Understanding the chemical vapor deposition cvd kinetics of graphene growth is important for advancing graphene processing and achieving better control of graphene thickness and properties in the perspective of improving large area graphene quality we have investigated in real time the cvd kinetics using ch 4 h 2 precursors on both polycrystalline copper and nickel.

Graphene cvd growth on copper.

Successfully grow the bernal bilayer graphene on the monolayer copper foil via layer by layer epitaxy.

In the perspective of improving large area graphene quality we have investigated in real time the cvd kinetics using ch 4 h 2 precursors on both polycrystalline copper and nickel.

12 a a graphene coated copper foils as the substrate was placed at the downstream for the subsequent epitaxial growth and another.

A ramping 40 min to target temperature 25 c min from room temperature a constant temperature period for graphene growth at 1035 1075 c and a cooling to room temperature for 90 min fig.

The major thermal process for cvd graphene growth includes 3 stages.

The copper substrate was mildly oxidized by exposure to hot ar that.

Understanding the chemical vapor deposition cvd kinetics of graphene growth is important for advancing graphene processing and achieving better control of graphene thickness and properties.

The cvd process is reasonably straightforward although some specialist equipment is necessary and in order to create good quality graphene it is important to strictly adhere to guidelines set concerning gas volumes.

Chemical vapour deposition or cvd is a method which can produce relatively high quality graphene potentially on a large scale.